Screw Compressor

Our Team

We have gained remarkable growth in the industry due to the constant efforts and hard work of our team members. Our company hires experienced and highly qualified people so that we can meet the increasing demands of our clients. The team members understand the requirements of our valuable customers and produce products as per the specifications provided. we regularly conduct training sessions for our personnel to upgrade their skills and Knowledge, also our workforce keeps updating itself with the current trends of the market and the latest technologies.

Our efficient team comprises: !

- Mechanical Engineers

- Designers

- Quality Controllers

- Raw Material Procurement experts

- Skilled Laborers

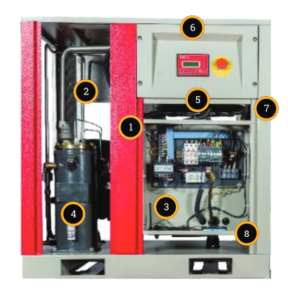

SCREW COMPRESSOR

1.AIR FILTERS

Designed to provide the highest efficiency in airfiltration, filter media is made from best quality raw materials.

2.OIL FILTERS

Reliability under stringent requirements, Tried and tested in operation, Robust design with Efficient separation and high dirt holding capacity at low pressure drop with Undetachable seals and Bypass valve with clearly defined opening characteristic,Robust metal housing with integrated filter element made up of Glass fiber medium, Resistance to aggressive compressor oils with high separation performance, Expected Service life approx. 4,000 hours with Improved pulsation resistance.

3.CONTROL PANEL

State-of-the-art electrical control panel using Schneider/ Siemens products with safety protections

4.AIR OIL SEPARATION SYSTEM

Efficient separation of air and oil is achieved by Centrifugal, Gravity and filtration done inside the

small sized vertical oil vessel to ensure delivering the oil free air consistently while increasing the separator element life with low pressure drop and lowering the air loses during load/unload cycle.

5.EFFICIENT COOLING SYSTEM

Cooling fan motor controlled by microprocessor based on airend temperature, ensuring optimum discharge temperature while increasing the oil life.

6.ADVANCED CONTROLER

State-of-the-art control & monitoring thanks to the latest RMP 1.0 / RMP 4.0 with built-in connectivity, Service and warning indications, error detection and compressor shut-down, reverse rotation protection, motor imbalance protection, voltage protection, maintenance scheduling,

current monitoring, phase lag protection, high temperature protection.

7.AUTO ADJUSTABLE INTAKE VALVE

Auto adjustable intake valve with integrated solenoid control, blow down valve and actuator is designed for low losses, controls the capacity during start up to reducing the no-load power.

8.REMOTE MONITORING SYSTEM

It is a small high-tech patented gateway integrated with each and every compressor controller and capture all compressor parameters and this real-time data along with detailed analysis, reports and alerts will be monitored by RMP and dealer network team to manage service schedules, parts requirements and provide early detection of compressor abnormalities through predictive maintenance analysis to the end users to achieve the maximum uptime.

Minimum Investment

Local Support Service

Latest Technology

Lower Maintenance Cost

Lower Spares Cost

Motor Speed = Airend Speed

- Direct Drive

- No Belts or Gears

- No transmission losses

- No Frictional loses

- Less Maintenance Cost

- Less Maintenance Cost

5/6 profiles

- Lower inter-lobe leakage losses

- Larger Wrap Angle

- Reduction in Vibration, Noise, Wear & Tear

- Larger Discharge Port

- Increase the overall compressor efficiency

- Larger Rotor Size

- Consumes lower specific power